Couplings

Fenner couplings are designed to absorb shock loadings, accommodate drive misalignment and allow separation of the drive line for maintenance. Fenner shaft couplings range from highly resilient to rigid and are all precision manufactured using high quality cast iron or steel, and the latest polymer and composite technology. |

Fenaflex Tyre Couplings

|

Fenaflex Tyre Couplings are highly elastic, lubrication free couplings that tolerate large amounts of misalignment in all planes as well as offering simple installation and inspection without disrupting the drive. The Fenaflex™ coupling also has excellent shock absorbing properties while reducing vibration and torsional oscillations.

- Simple time saving installation - motor and machine remains undisturbed whilst tyre is changed

- Large misalignment capability, 4° angular, up to 6mm parallel and 8mm axial

- Internal load carrying cords are wound in both directions, so there is no problem on reversing drives

- Tyres are available in standard and FRAS (Fire Resistant Anti Static) construction. ATEX approved.

- Simple visual inspection to aid maintenance

- Taper Lock® and pilot bore flanges

- Lubrication free

- Pump spacer and flywheel fixing variants available

|

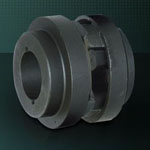

Jaw Couplings |

Jaw Couplings

Absorbing incidental misalignment, shock loads and small amplitude vibrations, Fenner Jaw couplings offer a low cost flexible solution for most applications.

- Ease of alignment

- Fail-safe shaft connection

- Range of element materials available including nitrile, urethane and Hytrel

- Pump spacer variant available

- Quick-fit wrap around element available

- Design powers up to 42.2kW available at 1440rpm

|

HRC Couplings HRC Couplings

|

HRC Couplings

Permitting quick and easy installation by means of Taper Lock® bushes, and offering quick alignment, the semi-elastic general purpose HRC coupling is ideal for use with electric motors.

- Offers the simplest, most straightforward fitting available

- Ease of alignment and fitting using straight edge and machined outside diameters

- Fail-safe design due to interacting dog design

- Accommodates incidental misalignment

- Exceptional performance at low cost

- Power ratings are matched to standard motor sizes

- Standard and FRAS elements available

- Flywheel fixing variant available

- Pilot bore design also available

|

Rigid Couplings

|

Rigid Couplings

Taper Lock® rigid couplings provide a convenient method of rigidly connecting the ends of shafts. Taper Lock® bushes permit easier and quicker fixing to the shafts with the firmness of a shrunk-on-fit.

- Taper Lock® fixing as standard

- Peripheral speeds of up to 33m/s available

- 8 sizes in the range

- Vertical assemblies possible in FF design.

|

|

|